Ovens

Termopan equipment uses the most advanced technology to guarantee the highest quality and productivity in the baking and pastry industry.

Our equipment meets the manufacturing needs for efficient and high-quality production. We proudly serve clients all over the world who are actively making a wide variety of products: lavash, baguettes, pizzas, croissants, tiger bread or pasteis de nata among others.

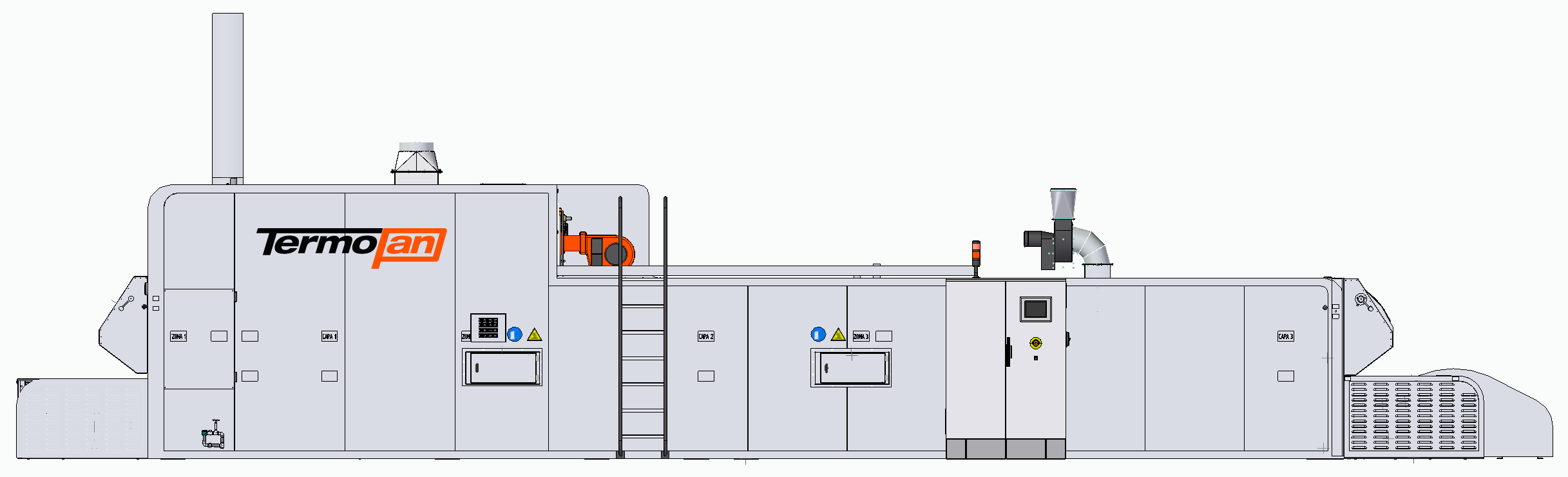

Termopan has been designing and making tunnel ovens since 1982. As a result, it has always had a close relationship with the sector. Every tunnel oven is designed and built according to the specific requirements of whatever product is going to be baked.

Termopan offers extremely versatile ovens in terms of the oven’s surface, heat transfer (cyclothermic, DGF, convection, infrared), control configuration, temperature curve configuration, speed range, etc.

High production Tunnel Ovens

Termopan ovens have advanced baking and monitoring technology integrated throughout the entire tunnel. Termopan provides simplification in baking through our KBB Knowledge Based Baking technology making it possible to design a specific type of cooking for each product, simultaneously configuring the optimal equipment for your cooking.

KBB is an intelligent system which calculates and recommends dimensions based on different requirements, the type of heat transfer and which kind of loading belt to use.

Our commercial staff use KBB to advise our clients on what type of oven is necessary for them.

This combination of factors any type of oven solution for any kind of product.

In Termopan we like challenges. As a result, we are always committed to developing ways of industrializing production processes of local products which until now have been produced in an artisan way.